Understanding Billet Sags: Causes, Prevention, and Solutions

Billet sags, a common issue in the metalworking and manufacturing industries, can lead to significant production inefficiencies and quality control problems. Understanding the causes, implementing preventive measures, and applying effective solutions are crucial for maintaining operational excellence. This article delves into the complexities of billet sags, providing a comprehensive overview for professionals in the field.

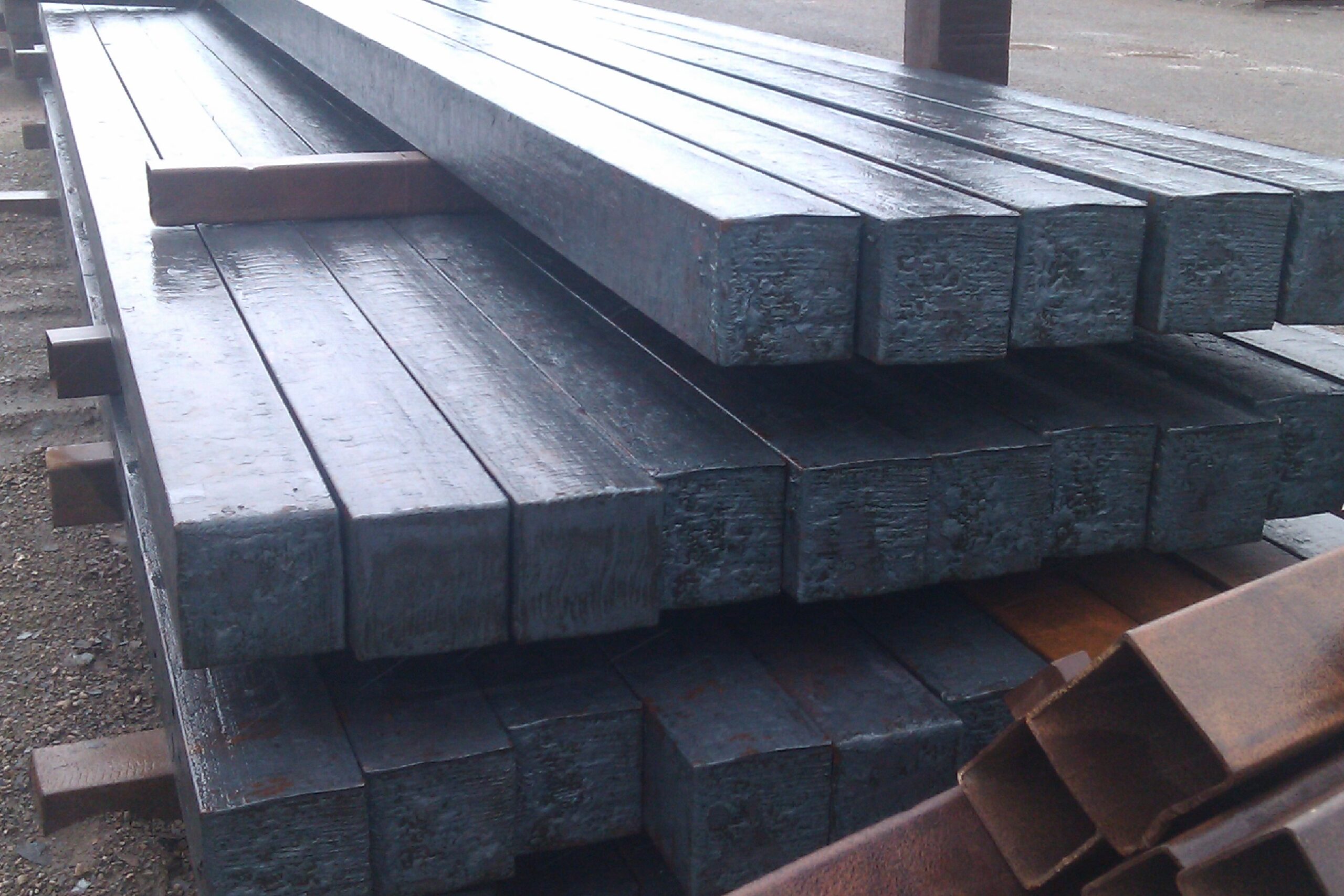

What are Billet Sags?

A billet sag refers to the deformation or bending of a metal billet during heating, handling, or processing. Billets are semi-finished metal products, typically rectangular or square in cross-section, used as raw material for further manufacturing processes like rolling, forging, or extrusion. When a billet undergoes excessive sagging, it can compromise the dimensional accuracy of the final product, leading to increased scrap rates and higher production costs. The phenomenon of billet sags is influenced by factors such as temperature, material properties, support mechanisms, and the duration of exposure to elevated temperatures.

Causes of Billet Sags

Several factors contribute to the occurrence of billet sags. Identifying these causes is the first step in developing effective mitigation strategies.

Temperature

Temperature plays a critical role in the mechanical properties of metals. As temperature increases, the yield strength and creep resistance of the billet material decrease, making it more susceptible to deformation under its own weight or external loads. Overheating billets beyond their recommended temperature range can exacerbate the problem of billet sags.

Material Properties

Different metals and alloys exhibit varying levels of resistance to deformation at elevated temperatures. Materials with lower creep resistance are more prone to sagging. The chemical composition, grain size, and prior processing history of the billet material also influence its susceptibility to billet sags. For example, certain grades of steel or aluminum alloys may exhibit a higher tendency to sag compared to others.

Support Mechanisms

The design and effectiveness of the support mechanisms used to hold the billets during heating and handling significantly impact the likelihood of sagging. Inadequate or poorly designed supports can create stress concentrations, leading to localized deformation. The spacing between supports, the material of the supports, and the contact area between the supports and the billet are all critical factors to consider. Insufficient support leads to inevitable billet sags.

Heating Duration

The length of time a billet is exposed to elevated temperatures also contributes to the risk of sagging. Prolonged exposure allows more time for creep deformation to occur, increasing the magnitude of the sag. Optimizing heating cycles to minimize the duration of exposure while still achieving the desired temperature uniformity is essential. Leaving billets in the furnace for extended periods virtually guarantees billet sags.

Billet Dimensions

The dimensions of the billet, particularly its length and cross-sectional area, influence its susceptibility to sagging. Longer billets are more prone to sagging due to the increased bending moment caused by their own weight. Similarly, billets with smaller cross-sectional areas offer less resistance to deformation. Understanding these dimensional factors is crucial in designing appropriate support systems and heating strategies to prevent billet sags.

Prevention Strategies for Billet Sags

Preventing billet sags requires a multi-faceted approach that addresses the underlying causes. Implementing the following strategies can significantly reduce the occurrence of this problem.

Temperature Control

Maintaining precise temperature control during the heating process is paramount. This involves using calibrated thermocouples and temperature controllers to ensure accurate temperature readings and prevent overheating. Implementing temperature monitoring systems that provide real-time feedback can help operators identify and correct temperature deviations promptly. Properly calibrated equipment prevents billet sags by ensuring temperature uniformity.

Material Selection

Selecting billet materials with higher creep resistance at elevated temperatures can significantly reduce the risk of sagging. Consider the specific application requirements and choose alloys that offer superior performance under the expected operating conditions. Consulting with material scientists and metallurgists can help identify the most suitable materials for preventing billet sags.

Optimized Support Systems

Designing and implementing optimized support systems is crucial for preventing billet sags. This involves carefully considering the spacing between supports, the material of the supports, and the contact area between the supports and the billet. Using high-temperature alloys for the supports can minimize deformation and maintain their load-bearing capacity. Finite element analysis (FEA) can be used to optimize the support system design and identify potential stress concentrations. Proper support prevents billet sags by distributing weight evenly.

Heating Cycle Optimization

Optimizing heating cycles to minimize the duration of exposure to elevated temperatures can reduce the risk of sagging. This involves using rapid heating techniques, such as induction heating or radiant heating, to achieve the desired temperature uniformity quickly. Implementing preheating strategies can also reduce the overall heating time and minimize the potential for creep deformation. Reducing the time billets spend at high temperatures reduces billet sags.

Billet Handling Procedures

Implementing proper billet handling procedures can prevent damage and deformation during transportation and storage. This includes using appropriate lifting equipment, handling billets with care, and avoiding dropping or impacting them. Storing billets on flat, level surfaces can also prevent sagging. Careful handling minimizes stress and prevents billet sags.

Solutions for Addressing Billet Sags

Despite preventive measures, billet sags can still occur. Implementing effective solutions to address this issue is crucial for minimizing production losses and maintaining product quality.

Straightening and Reconditioning

In some cases, slightly sagged billets can be straightened and reconditioned for further processing. This involves using hydraulic presses or other specialized equipment to apply controlled forces and restore the billet to its original shape. However, this process can introduce residual stresses and may not be suitable for all materials or applications. Straightening can correct minor billet sags.

Remelting and Recasting

For severely sagged billets, remelting and recasting may be the only viable option. This involves melting the billet and recasting it into a new shape. While this process can recover the material, it is energy-intensive and may not be cost-effective for all applications. Remelting is a last resort for extreme billet sags.

Material Downgrading

In some cases, sagged billets can be downgraded to less demanding applications where dimensional accuracy is not as critical. This can help salvage the material and avoid complete scrapping. However, this option may not be suitable for all materials or applications. Careful evaluation is required to determine if downgrading is a viable solution for dealing with billet sags.

Process Adjustments

Analyzing the root cause of the billet sags and making adjustments to the heating, handling, or support processes can prevent future occurrences. This may involve modifying the heating cycle, improving the support system design, or implementing more stringent quality control measures. Continuous improvement is essential for minimizing the risk of sagging. Regular process review can minimize future billet sags.

Case Studies

Several case studies highlight the importance of understanding and addressing billet sags. One case involved a steel manufacturer experiencing high scrap rates due to excessive sagging during the preheating of large billets for forging. By implementing a combination of improved temperature control, optimized support systems, and shorter heating cycles, the manufacturer was able to reduce scrap rates by 40%.

Another case involved an aluminum extrusion company that was experiencing dimensional inaccuracies in its final products due to sagging of the aluminum billets during heating. By switching to a higher-strength aluminum alloy and implementing a more robust support system, the company was able to eliminate the sagging problem and improve the quality of its extruded products. These case studies illustrate the significant impact that proactive measures can have on mitigating the risks associated with billet sags.

Future Trends

The future of billet heating and handling is likely to be shaped by advancements in technology and a greater emphasis on process optimization. The increasing use of automation and robotics can improve precision and consistency in billet handling, reducing the risk of damage and deformation. The development of more advanced heating technologies, such as induction heating and infrared heating, can enable faster and more uniform heating, minimizing the duration of exposure to elevated temperatures. Furthermore, the integration of data analytics and machine learning can provide real-time insights into the heating process, allowing for proactive adjustments to prevent billet sags.

Conclusion

Billet sags can pose significant challenges to metalworking and manufacturing operations. By understanding the causes, implementing preventive measures, and applying effective solutions, manufacturers can minimize the occurrence of this problem and maintain operational excellence. Temperature control, material selection, optimized support systems, heating cycle optimization, and proper handling procedures are all crucial elements of a comprehensive strategy for preventing billet sags. Continuous improvement and a proactive approach are essential for minimizing the risks associated with sagging and ensuring the production of high-quality metal products. [See also: Metal Forming Processes] [See also: Heat Treatment of Metals] [See also: Quality Control in Manufacturing]